Nailing

Various uses

The nailing technique may be used in several cases:

– rock section or rock mass stabilization,

– landslide treatment,

– stabilization of retaining walls exposed to a pushing force,

– compensating horizontal strains exercised on a structure,

– setting up prevention devices

The mechanics of nailing

Nails may be exposed to two types of forces:

– shear strains

and/or

– traction strains.

Differences between nails and ground anchors

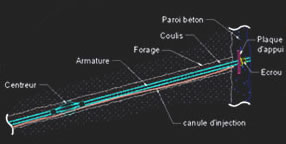

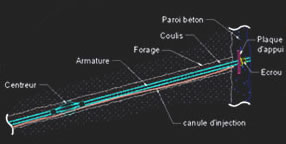

- Nails are sealed along the whole length of the drilled hole and generally have a high-adherence bar. Only slight prestressing and locking may be applied to this type of anchoring device.

– Ground anchors have a sealed part and an unsealed part. Prestressing which may at times be significan is sometimes applied in order to generate stress on the environment between the support surface and the sealed area. The armature may consist of bars or cables. The absence of sealing generally makes it necessary to provide a particular protection for the armature (P2).

(As mentioned MTPS is able to install nails or ground anchors, depending on the objectives being sought.)

|

Casing

If the environment is not stable, the use of temporary casing may be necessary to retrieve the drilling material and to set up the armature. This objective can be attained by implementing ODEX, a technique that makes it possible to use a casing as work progresses.

Corrosion

The metal armatures in use are susceptible to corrosion. Hence two approaches are possible:

– Taking into account that the outer layer will be subjected to corrosion and wear off when calculating dimensions;

– Installing a protective casing (of the P2 type for instance).

Injection

The anchor must be covered in grout to ensure that the armature remains sealed to the ground. This technique protects the armature against corrosion, and makes it possible to transfer the strains to the ground.

Several types of injection are possible:

- Gravitational injection,

-GSI (Global Single Injection) from the bottom of the hole using a polyethylene hose,

– SRI (Selective Repeated Injection) meaning the grout is injected into drilled holes at a given pressure.

Connexions with the structures

Any type of anchor requires a more or less significant absorber base. It may be a simple supporting plate used when bolting the anchor to a hard rock mass. In case of poor-quality soils or ground, projected-concrete walls or even sills shall be built in to spread out the strain resulting from the anchors being installed.

|

Self-drilling nails

Self-drilling nails are useful in certain types of soils as they make it possible to resort to drilling techniques which involve the use of a casing as work progresses. The bit which makes drilling possible is lost.

A few figures

- drilling diameters from 64 to 140 mm

– armature diameters 22 to 50 mm

– inclines comprised between 10 y 25°

Typical resistance values for a nail driven 2 m into a particular terrain :

| Drill diameters |

90 mm |

120 mm |

| When sealed to rock |

6 tons |

8 tons |

| When sealed into the soil |

1 ton |

1,2 tons |

|

Gilles's advice about self-drilling nails : Gilles's advice about self-drilling nails :

« Grout must be injected constantly while self-drilling nails are installed to ensure both the strength of the drill hole and proper injection for the whole of the anchor. It is to be noted that where this technique is used installations have a shorter life-span and are more susecptible to abrasion from contact with the surrounding terrain"

|

|

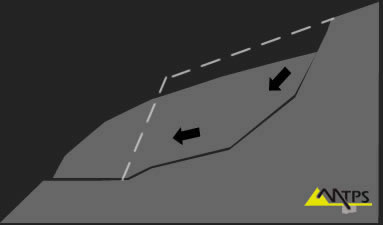

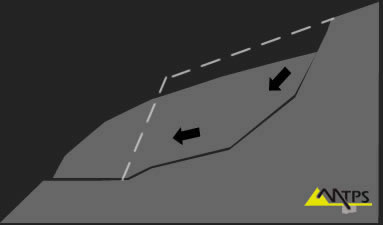

Example of landslide treatment

Ordinary landslide treatment scheme using progressive nailing and levelling out.

Put the cursor on the different phases to visualize the successive stages of treatment.

Initial phase : a landslide has occurred on a road, causing it to be completely closed to traffic. The unstable mass is too large to be leveled out and removing it might cause the phenomenon to extend up the road. The nailed wall technique is hence privileged.

|

|